时间:2023-08-15来源:昂科机床 作者:

August 2023 – CNC grinding technology pioneers ANCA will showcase their latest products, and industry-specific grinding and automation solutions at EMO (Stand F52, Hall 6). Excitingly, the winner of the renowned Tool of the Year competition will be announced live Wednesday 20 September at 4.30pm (GMT)–and all are welcome to join the celebrations and witness for themselves the ultimate range of cutting tools.

2023年8月——数控磨削技术先驱ANCA将在EMO(6号展厅F52号展位)展示其最新产品以及特定行业的磨削和自动化解决方案。令人兴奋的是,现场将宣布著名的年度刀具比赛的获胜者。9月20日星期三下午4点30分(格林尼治标准时间),欢迎所有人加入庆祝活动,亲眼目睹终极刀具系列。

Edmund Boland, ANCA CNC Machines General Manager said, “We are excited to bring not one but several world premieres to EMO, promising premium value, higher productivity and extended capabilities. Visitors can see firsthand ANCA’s latest technology that spans tool precision, integrated manufacturing systems, industry focus applications and optimisation across the process chain.”

ANCA数控磨床总经理埃德蒙·博兰德表示:“我们很高兴能为EMO带来不止一场而是几场的全球首映式,向客户承诺提供优质价值、更高的生产力和扩展的能力。大家可以亲眼看到ANCA的最新技术,涵盖了刀具精度、集成制造系统、行业重点应用和整个工艺链的优化。”

Martin Winterstein, General Manager of ANCA Europe said, “EMO is the global leading manufacturing technology show, it is where the current market trends and innovations are on display. Our setup in Hannover really shows hands-on opportunities for tool manufacturers, with new application and automation solutions tailored to industries’ needs. I am excited to show visitors our enhanced portfolio to include micro tools with the FX ULTRA, according to the high demand from this growing segment. Experts from ANCA and our partners will be on-site to show and discuss individual requirements at the stand.”

ANCA欧洲总经理马丁·温特斯坦表示,“EMO是全球领先的制造技术展,它展示了当前的市场趋势和创新。我们在汉诺威的展厅为制造商展示了刀具制造的成功工艺,提供了适合行业需求的新应用和自动化解决方案。ANCA将向参观者展示包括了生产微刀具的FX ULTRA等增强的产品组合,这一细分市场的需求在不断增长。ANCA的专家和合作伙伴们将在现场讨论并展示如何满足客户的特殊需求。”

ULTRA value

物有所值

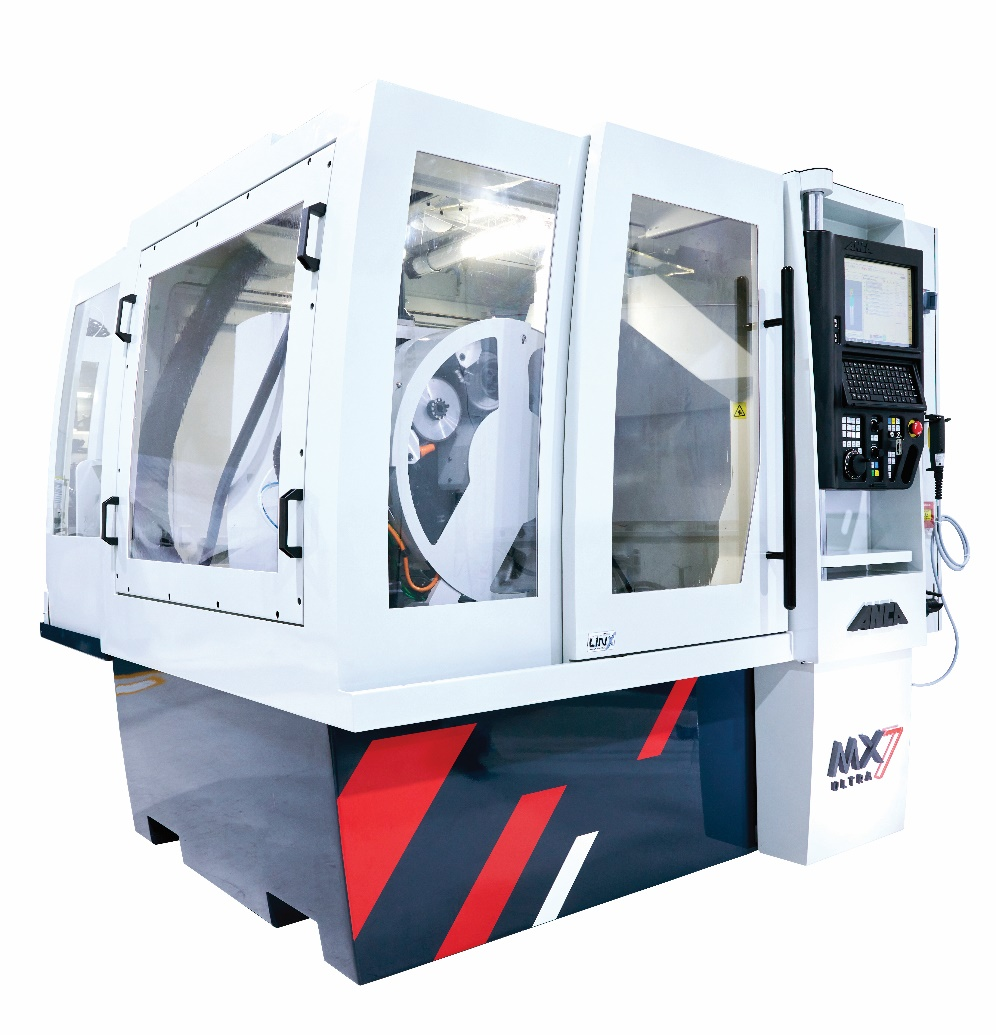

Never ceasing in their commitment to creating the highest quality product, years of continuous refinements at ANCA have made the ULTRA technology possible. ANCA’s unique vertical integration is key to its success - where machines, controls, drives and precision components are all designed and manufactured in-house. Successfully introduced to the industry last year on the MX machine platform, it boasts the highest accuracy and quality cutting tools in the world. In fact, the MX7ULTRA achieves one nanometre axis resolution, and can maintain better than +/- 0.002mm line form accuracy of any profile which includes ballnose and corner radius endmills.

ANCA从未停止过对创造最高质量产品的承诺,多年来的不断完善使ULTRA技术成为可能。ANCA独特的垂直整合是其成功的关键——磨床、控制、驱动和精密部件都是在内部设计和制造。去年推出的MX平台能生产世界上最高的精度和质量的切割刀具。事实上,MX7 ULTRA实现了1纳米的轴分辨率,并能保持任何型材的+/- 0.002毫米的精度,包括球头铣刀和圆角铣刀。

At EMO, visitors will find out how ANCA spreads the ULTRA advantages to further fields of application, including smaller batches, regrinding and tools with small diameters.

在EMO展会上,参观者将了解到ANCA如何将ULTRA的优势推广到更多的应用领域,包括小批量、重磨和小直径的刀具的生产。

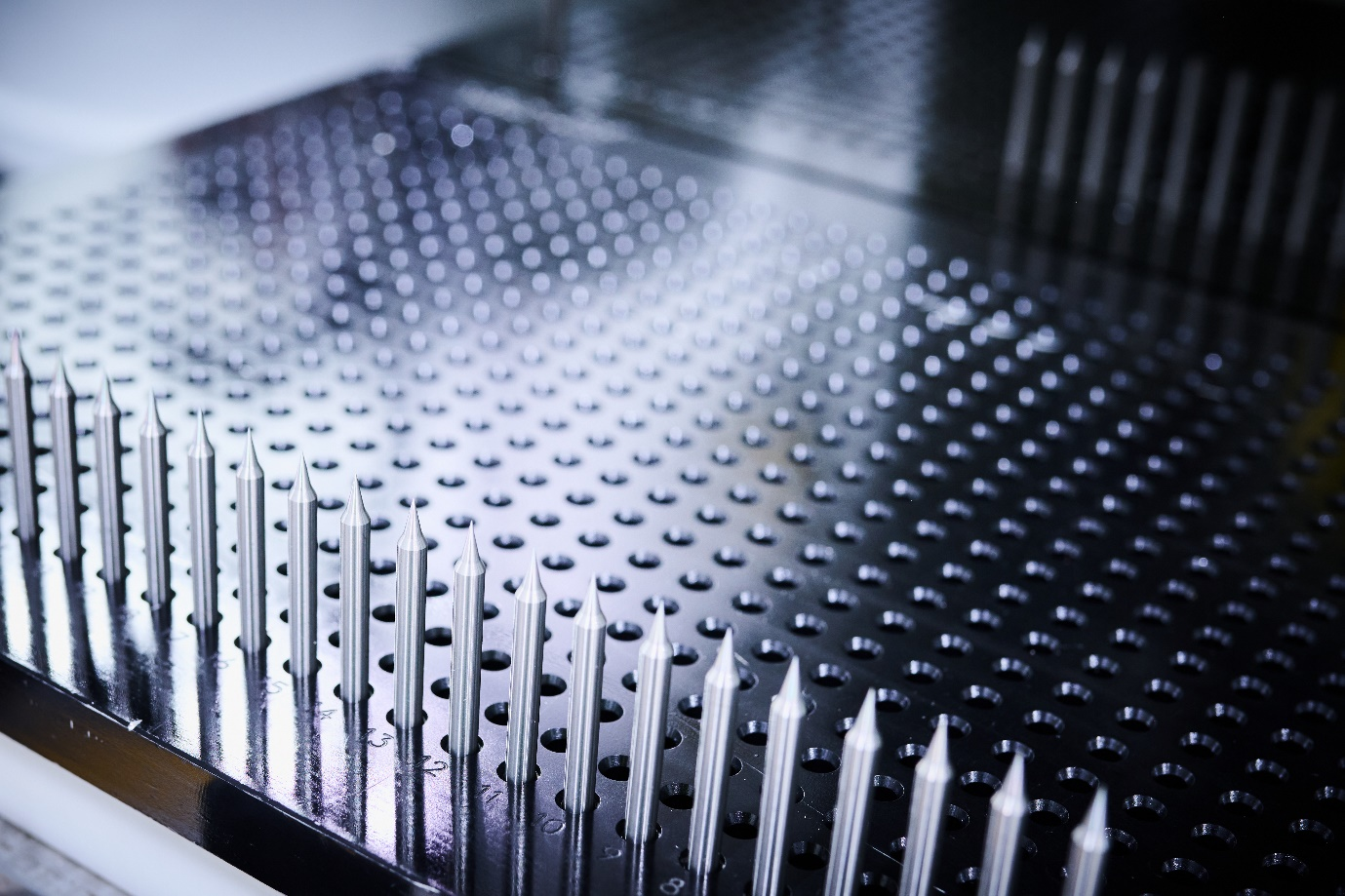

Launching the FX7 ULTRA, the latest game-changing innovation that guarantees perfection for small tools down to 0.1mm

FX7 ULTRA,最新的改变游戏规则的创新产品,完美生产小到0.1毫米的小型刀具。

The FX7 ULTRA introduces cutting-edge technologies, including ANCA’s unique nanometer control, that revolutionise precision grinding for small and micro tools down to 0.1mm diameter. This significant technology breakthrough is already redefining the standards for tool and component grinding with the highest levels of accuracy and surface finishes.

FX7 ULTRA引进了尖端技术,包括ANCA独特的纳米控制技术,彻底改变了小到0.1毫米直径的小型和微型刀具的精密磨削。这一重大的技术突破已经重新定义了刀具和零件磨削的标准,具有最高的精度和表面光洁度。

New software, hardware and design features significantly improve surface finish, accuracy, and controlled runout, ensuring batch consistency from the first ground tool to the last. These advancements ensure that the FX7 ULTRA is the go-to solution for precision grinding in industries that rely on small tools, including electronics, telecommunications, medical devices, aerospace, automotive, diemold, and general machining.

新的软件、硬件和设计大大改善了表面光洁度、精度和跳动可控性,确保了从第一把刀到最后一把刀的批量一致性。FX7 ULTRA是小型刀具生产商的精密磨削首选解决方案,包括电子、电信、医疗设备、航空航天、汽车、模具和普通加工等行业。

The ultimate value – ANCA’s premium one stop shop for peel and geometry combined with blanket grinding

物超所值——ANCA优质的一站式服务,包括剥离磨削和特殊几何形状加工以及棒料磨削

From blank to a finished high-quality tool, all on one machine – ANCA’s ultimate single setup solution for complete machining of cutting tools will be demonstrated on the MX7 ULTRA at EMO. Following a legacy of machine efficiency, this latest solution combines peel grinding and tool grinding on the one platform, enhanced with additional power to extend capability. The MX7 ULTRA's remarkable spindle power of 26kW can handle demanding tools like larger taper ballnose endmills, step drills, and aerospace components ranging from 0.1 to 25.4 mm. This leads to reduced cycle times and increased productivity. Short setup times, optional collet change and proven blanket grinding processes round out the capabilities.

一台磨床,完成从棒料到高质量的成品刀具的全部磨削—— ANCA终极一次设置完成所有加工步骤的解决方案——MX7 ULTRA,将在EMO上展示。秉承ANCA磨床高效率的传统,这一最新的解决方案在一个平台上结合了磨皮和刀具磨削两个功能,并通过额外的动力来扩展磨削能力。MX7 ULTRA卓越的主轴功率为26kW,可处理要求较高的刀具,如具有较大的锥度的球头铣刀、阶梯钻头和0.1至25.4毫米的航空部件。磨床减少了循环周期时间提高了生产率。同时缩短了设置时间,可选夹头自动更换功能和成熟的棒料磨削工艺使其能力更加完善。

By utilising the latest innovations in peel grinding technology, ANCA guarantees exceptional stability, accuracy and value, all achieved on a single machine. Manufacturers can now produce high-quality tools with confidence, knowing that the MX7 ULTRA delivers outstanding results.

ANCA利用剥离磨削技术的最新创新,提高了卓越的稳定性、准确性和价值,所有这些都是在一台机器上实现的。制造商现在可以放心地生产高质量的工具,因为他们知道MX7 ULTRA可以提供出色的结果。

Smart automation enables unattended cutting tool production

智能自动化实现无人值守刀具生产

ANCA has further developed its AIMS system for automated tool production. At EMO, visitors can see examples from the field, with systems operating completely unattended over extended period, manufacturing tools.

ANCA进一步开发了用于自动化刀具生产的AIMS系统。在EMO,客户可以看到现场演示,系统将在长时间内完全无人值守地运行,自动制造刀具。

The AIMS automation package is a modular and growing system, spanning across the tool production process. ANCA is set to include additional operations like blank preparation or laser marking in the automated process. The system’s intelligent design allows for progressive steps of automation, including an automated laser marking station AutoMarkX. The versatile laser marking station is tailored to meet the needs of tool manufacturers. It provides reliable and high-quality marking, ensuring traceability, identification, and branding of tools, while eliminating repetitive tasks to free up time for skilled staff.

AIMS自动化系统是一个模块化且不断发展的系统,包括了整个刀具生产过程。ANCA还进一步包括了额外操作的自动化过程,如棒料制备或激光标记。AIMS系统的智能设计允许逐步实现自动化,可以在主流程之后安装自动激光打标站AutoMarkX。多功能激光打标站是为满足市场需求而定制的。它提供了可靠和高质量的标记,确保了刀具的可追溯性、标识和品牌,同时消除了重复的人力劳动,为员工腾出了宝贵的时间。

The AutoMarkX’s new, retrofittable rotary workholding system allows for unlimited index marking around the tool, with automatic Z-axis focus and compatibility with tool shanks from 3 to 32mm. Moreover, the AIMS Autoline Basic, the standard interface for easy loading at the AutoMarkX enables customers to experience smoother material transfer between machines. By utilising a manual trolley system, combined with AIMS pallet carriers, Autoline Basic streamlines the transfer of heavy tool pallets between machines, reducing labour-intensive processes.

AutoMarkX新的可改装旋转工件夹持系统允许在刀具周围进行无限制的分度标记,具有自动Z轴聚焦功能,与3至32mm的刀柄兼容。此外,AIMS Autoline是在AutoMarkX轻松装载的标准接口,使客户能够体验到机器之间更顺畅的材料传输。通过使用手动推车系统,结合AIMS托盘搬运器,Autoline简化了重型刀具托盘在机器之间的转移,减少了劳动密集型流程。

From blanks with a surface finish better than 0.2Ra, to ANCA’s GCX Linear which has set the new benchmark for skiving cutter grinding

ANCA技术广泛应用于各个磨削领域,从为您提供表面光洁度优于0.2Ra的棒料的CPX,到为滚插刀磨削树立了新的基准的GCX Linear

ANCA's expertise in grinding solutions extends to blank grinding and integrated complete machining of gear tools, including in-process measuring and compensation. The CPX blank preparation machine will feature productivity-enhancing features in Hannover, including automated loading of tools up to 32mm, a flip station for grinding from both ends, tailstock, and extensive probing enabling statistic process control. The machine has been designed to give users high material removal rates, and save time and money with unattended production.

ANCA在磨削解决方案方面的专业知识囊括了从棒料磨削到齿轮刀具的集成完整加工,实现了各种刀具生产中的在线测量和补偿。CPX棒料制备机将在汉诺威展出,它具有更高的生产力,包括了高达32mm的刀具自动装载、用于从两端磨削的翻转台、尾座支架和实现统计过程控制的广泛探测等功能。CPX旨在为用户提供更高的材料去除率,实现无人值守生产来节省时间和金钱。

The rising demand of gear cutting tools has led ANCA to enhance its product program with the GCX, the turnkey solution for manufacturing and resharpening gear cutting tools. The Integrated Gear Tool Measurement (IGTM) and ANCA’s expertise in grinding wheel dressing gives customers the benefit of full control over the high precision skiving cutter grinding process. First skiving cutter in tolerance, is the motto. ANCA’s widely spread area of grinding applications, can be covered with the versatile GCX and its numerous optional accessories like the LaserUltra for profile tools.

为了满足齿轮刀具飞速增长的市场需求,ANCA加强了其GCX的产品计划。GCX是制造和重磨齿轮刀具的交钥匙解决方案。集成齿轮刀具测量(IGTM)和ANCA在砂轮修整方面的专业知识使客户能够完全控制高精度滚插刀的磨削过程。GCX,第一个台公差严格的滚插刀磨床。ANCA技术广泛应用于各个磨削领域, GCX还可选配众多其他配件(如用于成型刀具的LaserUltra),功能更加强大。

The Premier Cutting Tool Award

卓越的切削刀具奖项

One of the most eagerly awaited events at ANCA's stand will be the winner announcement of the Tool of the Year 2023 competition. This prestigious competition brings together tool manufacturers from around the globe, who compete for the title of the best real and virtual tools. The judging process, overseen by a panel of ANCA and external experts, evaluates precision, surface roughness, creativity, and practical use. The award ceremony promises to be a highlight of the exhibition, recognizing the industry's most innovative and exceptional tools.

ANCA展厅里最受期待的活动之一将是2023年年度刀具大赛的获胜者的宣布。这场久负盛名的比赛汇集了来自全球各地的刀具制造商,他们竞相争夺最佳刀具和虚拟刀具奖项。评判过程由ANCA和外部专家组成的评选组进行监督,评估刀具的精度、表面粗糙度、创造力和实用性。颁奖典礼将成为整个展会的一大亮点,表彰业内最具创新性和卓越性的刀具。

EMO 2023 offers an exclusive opportunity for industry professionals to explore ANCA's latest advancements in grinding technology, witness revolutionary world premieres, and engage with experts from the field. Visitors will also experience exclusive product launches to be revealed at the show. ANCA invites all attendees to visit their stand in hall 6, F52, where they can experience firsthand the cutting-edge solutions and industry-specific grinding innovations that are shaping the future of manufacturing.

2023 EMO为行业专业人士提供了一个独家机会,让他们充分探索ANCA在磨削技术方面的最新进展,见证革命性的世界首秀,与专家直接对话。参观者还将在展会上体验独家产品发布会。ANCA邀请所有与会者莅临参观位于F52 6号展厅的展位,在那里亲身体验正在塑造制造业未来的尖端解决方案和行业特定磨削创新。

Strategic Partnerships with Industry leaders

与行业领导者建立战略合作伙伴关系

ANCA's commitment to excellence is further emphasized through strategic partnerships with industry leaders. At EMO 2023, ANCA will collaborate with Mitsubishi, presenting their EDM machine at the stand, and GDS clamping technology, presenting a cohesive ecosystem of solutions that streamline processes across the process chain.

通过与行业领导者的战略合作,进一步加强了ANCA对追求卓越的承诺。在2023年欧洲磨床展上,ANCA将与三菱公司合作,在展台上展示他们的电火花加工机,以及GDS夹持技术,呈现一个具有凝聚力的生态系统,以简化整个加工链的流程。

The modular automation system AIMS is ANCA’s answer for tool manufacturers looking to increase their productivity, stay competitive and an be an attractive employer

模块化的自动化系统AIMS是ANCA提高生产力、保持竞争力的解决方案,使您成为一个更有吸引力的雇主。

The ULTRA package with nanometer resolution, design, software and quality features enable manufacturers to grind tools with very demanding specifications

具有纳米级分辨率的ULTRA,包括了设计、软件和质量控制,能够制造磨削规格要求极高的精密刀具

标签: 昂科机床

免责声明:凡注明(来源:齿轮头条网)的所有文字、图片、音视和视频文件,版权均为齿轮头条网(www.geartoutiao.com)独家所有,如需转载请与本网联系。任何机构或个人转载使用时须注明来源“齿轮头条网”,违反者本网将追究其法律责任。本网转载并注明其他来源的稿件,均来自互联网或业内投稿人士,版权属于原版权人。转载请保留稿件来源及作者,禁止擅自篡改,违者自负版权法律责任。